Our Services

Dry & Wet Risers and Hydrants

Wet & Dry Riser Installations

Wet and Dry rising mains are intended for use by the Fire Brigade or other trained personnel. They provide a readily available means of delivering considerable quantities of water to extinguish or to prevent the spread of fire.

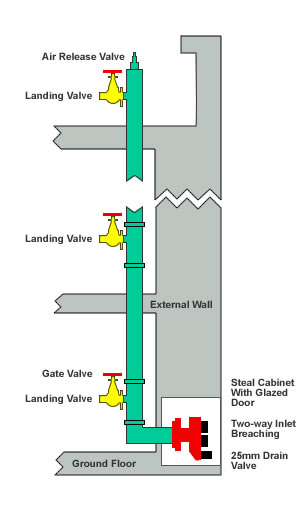

Dry risers are vertical mains fitted into staircase enclosures or other suitable positions, with outlet valves on each floor and inlets fitted at ground level to enable the fire brigade to connect to the water supply.

Wet risers are pipes kept permanently charged with water either from a storage tank (via a booster pump) or direct from the town's main water supply.

Before installing dry or wet rising mains the exact requirements of the local fire brigade must be ascertained.

Enquire about CT Fire Protection Wet & Dry Riser Installations

Wet & Dry Riser Inspections and Servicing

Dry or Wet Risers are a network of pipe work and valves that allow the fire service to easily and quickly deliver water to upper floor levels. The maintenance of these pipe networks and associated valves is essential to ensure they do not leak, can maintain the pressures required for fire fighting and are accessible for quick and easy connection. Ensuring the fire and rescue service have fast access to water supplies throughout your premises is one of the most effective ways of fighting fire.

British Standards recommend that service visits should be carried out every 6 months. Of the 2 visits recommended in a 12 month period, one is a major service, which would include more comprehensive tests such as the hydraulic pressure test. The other six monthly test includes visual checks which are highly recommended due to the accessibility of dry risers and their vulnerability to vandalism as they are usually in staircases and landings or other un-protected communal areas.

CT Fire Protection engineers carry out a full annual pressure tests and six monthly visual checks to the current British Standard Code of Practice BS9990:2006 using our own dry and wet riser testing appliance.

Wet Riser Systems

Wet riser systems are installed into new buildings above 50 metres or when it is difficult to provide a suitable breeching inlet position to a dry riser. Wet rising mains are intended for use by the fire brigade or other trained personnel and is kept permanently charged with water; either directly from a storage tank, via booster pumps or fed directly from the town's main water supply.

Wet riser tests include checks and tests on electrical equipment, storage tanks and pumps and these systems have to deliver higher pressures to higher floor levels.

Dry Riser Systems

A dry riser is a main vertical pipe intended to distribute water to multiple levels of a building or structure as a component of the fire suppression systems. Outlets are strategically placed to allow the fire service a connection on each floor to fight the fire directly from inside the building without manoeuvring hoses up through the building. Dry risers have to access a fire engine within 18m of the dry riser inlet box. Dry risers in occupied buildings have to be within a fire resistant shaft, usually one of a building's fire escape staircase enclosures.

BS 9990:2006 requires the system to undergo an annual static pressure test and inspection and a six monthly visual inspection, by a competent person. Thus ensuring the Dry riser system is maintained and functioning correctly for the fire brigade at all times.

If you would like to discuss your requirements or book in a service for your wet or dry riser equipment please contact us.

Hydrants

Large premises such as hospitals, universities or military establishments usually have private owned water hydrants installed on site for use by the Fire and Rescue Service in the event of a fire. It is an employer’s responsibility to ensure these are properly tested, and maintained by a competent person. It is essential that fire hydrants are not blocked from use from parked vehicles or bins for example.

An inspection of a fire hydrant looks at the hydrant pit, frame, cover, the surface surrounding the hydrant, the frost valve, if fitted, and the hydrant indictor plate will also be checked. All joints will be visually inspected for any signs of leakage.

Tests are carried out on a regular basis. The interval of inspection is left to individual fire authorities to determine. The agreed practice is that this will normally be carried out on an annual basis.

CT Fire operates a team of hydrant technicians who can test and inspect your water hydrants as part of your annual maintenance programme.

Enquire about CT Fire Protection Hydrants testing and maintenance.

V.A.T No. 847619292